Slitting saw DIN 1837 A

Materials: steel, cast, non-ferrous metals, plastic

Application: recommended for slotting fragile and hard materials which make short chips, suitable for cutting thin-walled profiles

Machine: metal processing machines

Characteristic:

Application: recommended for slotting fragile and hard materials which make short chips, suitable for cutting thin-walled profiles

Machine: metal processing machines

Characteristic:

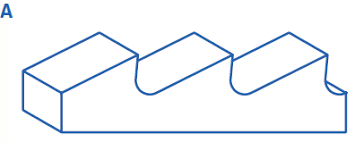

- Circular saw blades for metal with fine teeth

- hollow ground with a flange, standardly produced without driving pin holes and without a keyway

- tooth form A (by request AW)

- cutting edge is very sharp

- chip clearance is reduced and it can´t remove longer chips away from cutting area efficiently

- tolerances and hollow ground according DIN 1840

High quality slitting saw 1837 A, designed especialy for high performance. Slitting saws produced in Europe – Czech Republic.

Circular saw blades for metal DIN 1837 A with fine teeth and A tooth form are recommended for slotting fragile and hard materials. A tooth form is suitable especially for thin saw blades with tooth pitch from 0,8 mm to 3,0 mm. Cutting edge is very sharp. Chip clearance is reduced and it cannot remove longer chips away from the cutting area efficiently. In standard modification the slitting saw blades are made with hollow ground and with a flange. They can be ordered with driving pin holes or with a keyway and AW tooth form (the tooth form A with alternate chamfering).

HSS – circular saw blades for metal DIN 1837A – fine teeth |

|||||||||||||

| D (mm) | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 315 |

| dH7 (mm) | 5 | 8 | 8 | 10 | 13 | 16 | 22 | 22 | 22 | 32 | 32 | 32 | 40 |

| B (mm) | number of teeth | ||||||||||||

| 0,20 mm | 80 | 80 | 100 | 128 | 128 | ||||||||

| 0,25 mm | 64 | 80 | 100 | 100 | 128 | 160 | |||||||

| 0,30 mm | 64 | 80 | 80 | 100 | 128 | 128 | 160 | ||||||

| 0,40 mm | 64 | 64 | 80 | 100 | 100 | 128 | 160 | ||||||

| 0,50 mm | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | |||||

| 0,60 mm | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | ||||

| 0,80 mm | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | ||||

| 1,00 mm | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | 200 | ||

| 1,20 mm | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 | 200 | ||

| 1,60 mm | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 200 | 200 | |

| 2,00 mm | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 100 | 128 | 160 | 200 | |

| 2,50 mm | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 | 200 |

| 3,00 mm | 32 | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 160 | 160 | 200 |

| 4,00 mm | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 100 | 128 | 160 | 160 |

| 5,00 mm | 24 | 32 | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | 128 | 128 | 160 |

| 6,00 mm | 24 | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | 128 | 128 | 160 |

Small Slitting saws in imperial sizes according norms ASA teeth AFTe i.e. with fine pitch as to DIN 1837 Toothform A. Used for shallow cutting and cut-off operations. Hollow ground on both sides to prevent binding. |

|||||

| D (mm) | 3/4 | 1″ | 1 1/4 | 1 1/2 | 2″ |

| dH7 (mm) | 1/4 | 1/4 | 3/8 | 3/8 | 3/8 |

| B (mm) | number of teeth | ||||

| 0,006 | 40 | 50 | 60 | 72 | 100 |

| 0,008 | 40 | 50 | 60 | 72 | 100 |

| 0,1 | 40 | 50 | 60 | 72 | 100 |

| 0,01 | 40 | 50 | 60 | 72 | 100 |

| 0,012 | 40 | 50 | 60 | 72 | 100 |

| 1/6 4 | 40 | 50 | 60 | 72 | 100 |

| 0,02 | 40 | 50 | 60 | 72 | 100 |

| 0,025 | 40 | 50 | 60 | 72 | 100 |

| 1/3 2 | 40 | 50 | 60 | 72 | 100 |

| 3/6 4 | 40 | 50 | 60 | 72 | 100 |

| 1/1 6 | 40 | 50 | 60 | 72 | 100 |

| 5/6 4 | 40 | 50 | 60 | 72 | 100 |

| 3/3 2 | 40 | 50 | 60 | 72 | 100 |

| 7/6 4 | 40 | 50 | 60 | 72 | 100 |

| 1/8 | 40 | 50 | 60 | 72 | 100 |

| 5/3 2 | 72 | 100 | |||

| 3/1 6 | 72 | 100 | |||

| 7/3 2 | 100 | ||||

| 1/4 | 100 | ||||

Small Slitting saws in imperial sizes according norms ASA teeth AFTe i.e. with fine pitch as to DIN 1837 Toothform A. Used for shallow cutting and cut-off operations. Hollow ground on both sides to prevent binding. |

|||||||||||||||

| D (mm) | 2 1/2 | 3″ | 3 1/2 | 4″ | 4″ | 4 1/2″ | 4 1/2″ | 5″ | 6″ | 6″ | 7″ | 7″ | 8″ | 8″ | 10″ |

| dH7 (mm) | 1″ | 1″ | 1″ | 1″ | 1″ | 1 1/4″ | 1″ | 1″ | 1 1/4″ | 1 1/4″ | 1″ | 1 1/4″ | 1″ | 1 1/4″ | 1″ |

| B (mm) | number of teeth | ||||||||||||||

| 1/6 4 | 62 | 74 | 100 | 100 | |||||||||||

| 1/3 2 | 62 | 74 | 88 | 100 | 100 | 124 | 150 | ||||||||

| 3/6 4 | 62 | 74 | 100 | 124 | 150 | ||||||||||

| 1/1 6 | 62 | 74 | 88 | 100 | 100 | 124 | 150 | 176 | 176 | 200 | 250 | ||||

| 5/6 4 | 74 | 100 | |||||||||||||

| 3/3 2 | 62 | 74 | 100 | 112 | 124 | 150 | |||||||||

| 7/6 4 | 100 | ||||||||||||||

| 1/8 | 62 | 74 | 100 | 100 | 112 | 124 | 150 | 150 | 200 | 200 | 250 | ||||

| 5/3 2 | 62 | 74 | 100 | 124 | |||||||||||

| 3/1 6 | 74 | 100 | 124 | 150 | 150 | ||||||||||

| 7/3 2 | 74 | 176 | |||||||||||||

| 1/4 | 62 | 74 | 100 | 124 | 150 | 150 | |||||||||

Slitting saws range is ø 20 mm – ø 315 mm with thicknesses ranging 0,2 mm – 6 mm in variable designs with tooth forms: A – B – BW. All standard saws are available ground only but they are also available with VAPO or P.V.D. (Physical Vapour Deposition) coated execution. The above-mentioned examples of slitting saws are only a small overview of our production posibilities.

We are ready to produce also different tools according to your documentation like prismatic cutters, gear milling cutters, profile cutters, shell end mills cutters, side and face milling cutters, halfcircle milling cutters convex, half circle milling cutters concave, corner rounding milling cutters, single angle milling cutters, double angle milling cutters , HSS Side Chip Clearance Saws straight teeth, Slitting saw, M2 Side Chip Clearance Saws staggered tooth, HSS Side and Face Cutters straight teeth, HSS Side and Face Cutters staggered teeth.

We are ready to produce also different tools according to your documentation like prismatic cutters, gear milling cutters, profile cutters, shell end mills cutters, side and face milling cutters, halfcircle milling cutters convex, half circle milling cutters concave, corner rounding milling cutters, single angle milling cutters, double angle milling cutters , HSS Side Chip Clearance Saws straight teeth, Slitting saw, M2 Side Chip Clearance Saws staggered tooth, HSS Side and Face Cutters straight teeth, HSS Side and Face Cutters staggered teeth.