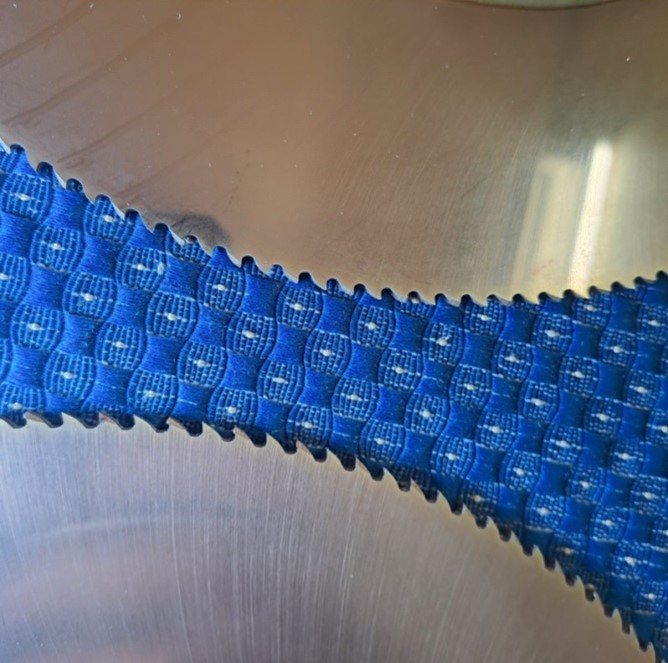

Slitting saw DIN 1838 B

Materials: steel, cast, non-ferrous metals

Application: recommended for slotting and cutting materials which make longer chips, suitable for cutting thick-walled profiles (wall over 2 mm)

Machine: metal processing machines

Characteristic:

- HSS circular slitting saw blades with rough teeth

- hollow ground with a flange, standardly produced without driving pin holes and without a keyway

- tooth form B (by request BW)

- compared to type A chip clearance is reduced, which allows to remove chips away from cutting area efficiently

- tolerances and hollow ground according DIN 1840

High quality slitting saw DIN 1838 B, designed especially for high performance. Slitting saws produced in Europe – Czech Republic.

Circular saw blades for metal DIN 1838 B with rough teeth and teeth form B are recommended especially for cutting-off steels. In comparison with A tooth form they have much bigger chip clearance and they enable bigger cut. In standard modification the saw blades are made with hollow ground and with a flange. They can be ordered with BW tooth form (B tooth form with alternate chamfering).

HSS – circular saw blades for metal DIN 1837A – fine teeth |

|||||||||||||

| D (mm) | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 315 |

| dH7 (mm) | 5 | 8 | 8 | 10 | 13 | 16 | 22 | 22 | 22 | 32 | 32 | 32 | 40 |

| B (mm) | number of teeth | ||||||||||||

| 0,50 mm | 48 | 64 | 64 | 80 | |||||

| 0,60 mm | 48 | 48 | 64 | 80 | 80 | ||||

| 0,80 mm | 40 | 48 | 64 | 64 | 80 | ||||

| 1,00 mm | 40 | 48 | 48 | 64 | 80 | 80 | |||

| 1,20 mm | 40 | 40 | 48 | 64 | 80 | 100 | |||

| 1,60 mm | 32 | 40 | 48 | 48 | 64 | 80 | 80 | 100 | |

| 2,00 mm | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 | |

| 2,50 mm | 32 | 32 | 40 | 48 | 64 | 64 | 80 | 80 | 100 |

| 3,00 mm | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 80 | 100 |

| 4,00 mm | 24 | 32 | 32 | 40 | 48 | 48 | 64 | 80 | 80 |

| 5,00 mm | 24 | 24 | 32 | 40 | 40 | 48 | 64 | 64 | 80 |

| 6,00 mm | 20 | 24 | 32 | 32 | 40 | 48 | 48 | 64 | 80 |

HSS slitting saws coarse with Coarse Pitch as to DIN 1838 Toothform B. Used for medium deep cutting and cut-off operations. Hollow ground on both sides to prevent binding. |

||||||||||||||||||

| D (mm) | 2 1/2 | 3″ | 3 1/2 | 4″ | 4″ | 4 1/2″ | 5″ | 5″ | 6″ | 6″ | 7″ | 7″ | 8″ | 8″ | 10″ | 10″ | 12″ | 12″ |

| dH7 (mm) | 1″ | 1″ | 1″ | 1″ | 1 1/4″ | 1″ | 1″ | 1″ | 1 1/4″ | 1 1/4″ | 1″ | 1 1/4″ | 1″ | 1 1/4″ | 1″ | 1 1/4″ | 1″ | 1 1/4″ |

| B (mm) | number of teeth | |||||||||||||||||

| 1/6 4 | 26 | 30 | ||||||||||||||||

| 1/3 2 | 26 | 30 | 32 | 36 | 38 | 40 | 44 | 44 | ||||||||||

| 3/6 4 | 26 | 30 | 32 | 36 | 38 | 40 | 44 | |||||||||||

| 1/1 6 | 26 | 30 | 32 | 36 | 36 | 38 | 40 | 40 | 44 | 44 | 48 | 52 | 52 | 62 | 62 | |||

| 5/6 4 | 26 | 30 | 32 | 36 | 36 | 40 | 44 | 48 | 48 | 52 | 52 | 62 | ||||||

| 3/3 2 | 26 | 30 | 32 | 36 | 38 | 40 | 40 | 44 | 44 | 48 | 48 | 52 | 52 | 62 | 62 | |||

| 7/6 4 | 26 | 30 | 32 | 36 | 44 | |||||||||||||

| 1/8 | 26 | 30 | 32 | 36 | 36 | 40 | 40 | 44 | 44 | 48 | 48 | 52 | 52 | 62 | 62 | 70 | 70 | |

| 5/3 2 | 30 | 32 | 36 | 40 | 44 | 44 | 48 | 52 | 62 | |||||||||

| 3/1 6 | 26 | 30 | 32 | 36 | 40 | 44 | 44 | 48 | 52 | 52 | 62 | 70 | ||||||

| 7/3 2 | 30 | 32 | 36 | 36 | 40 | 44 | 48 | 52 | 62 | |||||||||

| 1/4 | 26 | 30 | 32 | 36 | 40 | 44 | 44 | 48 | 52 | 52 | 62 | |||||||