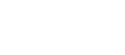

CIRULAR KNIVES AND BLADES

JOB OF THE MATEERIALS

Rubber, leather, paper, isolation materials and plastics, non-ferrous metals and steel.

Our rotary knives can be coated with PVD coatings (such as TIN, TICN, or TIALN) or with teflon depending on the many uses for which they are intended. Our circular knives are heat-treated to hardness 56-64 HRC in standard modification.

Our circular knives range in size from 20 mm to 600 mm (e.g. production of tinned vegetables or circular knives for cutting of deep-frozen products like fish, circular knives for meat etc.) These knives are round and made of stainless steel.

Due to the fact that these industrial knives are only produced upon request, it is crucial to include the following information in client queries or orders:

The circular knife’s diameter

The circular knife’s thickness, central bore diameter, driving pin hole diameter, number, and pitch, as well as the type of material that should be used for the blade’s body, its cutting edge variant, its cutting geometry, its cutting edge length, and the material that it should be used to cut with.

The typical modification does not disrupt the industrial knife’s cutting edge. It can have teeth like those seen on HSS circular saw blades for metal cutting, or it can have very particular tooth shapes. It is possible to create circular knives without teeth, as well as circular knives with grooves or ripples on the cutting edge.

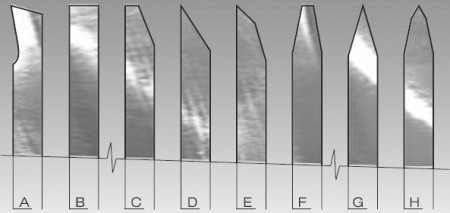

Depending on the type of material that the industrial knife is cutting, these blades’ cutting edges change. The specific edge variations we make for our industrial knives are displayed in the following table.

|

A |

industrial knives sided blade with undercut |

|

B |

square edge |

|

C |

single bevel blunt |

|

D |

single bevel sharp |

|

E |

double single bevel |

|

F |

double bevel blunt |

|

G |

double bevel sharp |

|

H |

double double bevel |

| Standard steel for the manufacture of blades: | |

| DIN 1.3343 | (HSS-Dmo5) |

| DIN 1.3243 | (HSS-Emo5) |

| DIN 1.2379 | (K 110) |

| DIN 1.2067 | (100 Cr6) |

| DIN 1.2080 | (X210Cr12) |

| DIN 1.4034 | (X40Cr13) |

| DIN 1.4112 | (X90CrVMo18) |